Three days after Kerala banned its drugs, CDSCO finds multiple violations during inspection at Maiden Pharma's Sonepat facility.

Maiden Pharmaceuticals Ltd, a Haryana-based company whose cough syrups are suspected to be the reason for death of 66 children in Gambia. (Wikimedia Commons)

Three days after Kerala halted the sale of all drugs and syrups of the company, a joint team of Haryana’s drugs controller and the Central Drug Standard Control Organisation (CDSCO) inspected the manufacturing facility of Maiden Pharmaceuticals on Tuesday, 11 October.

The inspection of the Kundli, Sonepat, facility of the company, which hit the headlines last week when WHO linked four of its cough syrups to the death of 66 children in the West African nation of Gambia, has found multiple violations.

The inspection followed a show cause notice sent to the company on 7 October, a copy of which is with South First.

“During inspection, many contraventions were detected (list attached). You are hereby served with a Show Cause Notice under Rule 85 (2) of Drug Rules, 1945 as to why your manufacturing license may not be suspended/cancelled,” says the notice issued by the State Drugs Controller-cum-Licensing Authority based in Panchkula, Haryana.

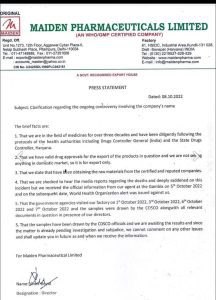

The inspection came two days after Vivek Goyal, a director at Maiden Pharmaceuticals, had expressed shock over the deaths of 66 children in Gambia and claimed the company “diligently followed” all protocols required for the manufacturing of drugs.

The authorities, during the inspection, found that the batch numbers, manufacturer name, manufacturing date and expiry date on the invoices of propylene glycol (used in cough syrups) were missing.

The authorities mention in the show cause notice that the firm “has not performed the quality testing of propylene glycol for diethylene glycol and ethylene glycol”.

If propylene glycol, which is usually used as a solvent in cough syrups, is contaminated with diethylene glycol and ethylene glycol, it can lead to death, which WHO found to be the reason behind the acute kidney failure leading to the deaths of the 66 children in Gambia.

According to a pharma expert, who did not want to be named, this also raises the question of how these findings could be missed by the licensing authority.

“As part of the CoPP (Certificate of Pharmaceutical Product) application, stability studies data must be provided; if so, what were the findings? I am sure the licensing authorities were hand-in-glove with the pharma company,” the expert told South First.

The authorities, during the inspection, also found that the complete plant was under renovation.

“The firm failed to produce the log books of equipment and instruments regarding manufacturing and testing for the drugs in question,” said the notice.

It was also found that the batch numbers of the propelygene glycol and sorbittol solution materials used in the manufacturing of cough syrups was not the same as the one mentioned on the Certificate of Analysis (CoA) report of the syrup.

“Batch numbers of Propylene Glycol IP and Sorbittol Solution (70 percent) IP in the CoA report number MPLR22031105 and MPLR22022301 respectively was not found mentioned, which was used in the manufacturing of the drug in question.”

Similarly, was the case with batch numbers of Sodium Methyl Paraben IP in the CoA report.

Maiden Pharmaceuticals had not performed process validation and analytical method validation for the drug products of these four cough syrups.

Maiden pharmaceuticals response to the WHO’s linking of 66 children deaths in The Gambia. The drug authorities found various violations. (ANI)

Meanwhile, the drug firm submitted the six-month, real-time and accelerate-stability data of the four cough syrups, but at the time of investigation none of these four cough syrups “found charged in the stability chamber”.

Explaining this, the pharma expert said: “For any drug/product to be approved by a licensing authority we need to provide evidence that my product has gone through the stability study.”

“This means, the product must be tested for it’s capability to remain within its physical, chemical, microbiological, therapeutic, and toxicological specifications at a defined storage condition. The product is usually kept in stability chamber for say one year to two years and later provide a report for the same. This company has not kept the products for charge in the stability chamber.”

Meanwhile, the firm, on the certificate of analysis of Propylene Glycol IP, had not given manufacturing and expiry dates in some cases. The authorities also found Propylene Glycol batch number E1105149 had been received and analysed on March 3, while the same analysis report was used for another drug.

Dinesh S Thakur is the whistleblower who exposed dangerous practices in the generic drug industry in 2012, and co-author of The Truth Pill: The Myth of Drug Regulation in India with public health activist Prashant Reddy T.

Though he appreciated the fact that the authorities conducted an inspection of the firm, he says such inspections have happened in the past as well and the final outcome of the process — whether they hold the firm accountable — is what matters.

“We have seen such inspections in the past as well; nothing really comes of it. Let’s hope this time something concrete happens to hold this firm accountable,” he told South First.

Thakur said that he found two observations made by the CDSCO authorities interesting.

One, he said, the report says that they did not find any products in the stability chamber while admitting that the company had submitted test results for accelerated stability studies when seeking marketing authorisation.

“I wonder how they created this data set if none of their products were being subjected to the stability testing process?”

The report also says that the firm has not performed process and analytical method validation on the drug products (syrups) in question.

“If their test methods were not validated, how did they do batch release? On what basis did they release batches of these syrups to Gambia?”

Oct 10, 2023

Sep 25, 2023

Jun 17, 2023

Jun 12, 2023

May 23, 2023

Feb 25, 2023